Amsterdam houseboats for annual lease, the Amsterdam apartment alternative

Amsterdam Houseboat rentals

Watergruwel 19M studio

Vrij Muselaer 25M 2 bed

Realengracht 25M 1 bed

Living on a houseboat in Amsterdam

Amsterdam woonboten te koop, houseboats for sale

Prevention of rust and corrosion of old steel barges in Amsterdam

“Electrolysis” of steel ships in the Amsterdam canals and harbor;

I’ve invested a lot of money and work into my boats, and I want to keep them. A man from Yacht Corrosion Consultants in California told me on the phone; “Your boat CAN last forever.” I like this idea a lot.

I’m sorry that there is no Dutch version of this site; if anyone is interested in translating it, please let me know.

I’ve been studying this for a while now, and I’ve read lots of books, talked to experts, and did my own measurements on my own boats in Amsterdam. Here’s what I found out;

Firstly, I have to say that electrolysis is what happens to the water [it’s split into oxygen and hydrogen], and it’s not what we boat owners are worried about.

What we are concerned with is called “Electrolytic corrosion”, also known as RUST!

Rust is not caused by water; it is caused by electricity. Water does allow electricity to flow in and out of your hull. The result is rust.

Metal will rust in wet air, but not in dry air. Dry air does not conduct electricity.

There are 2 sources of corrosive electrical current that we ship owners need concern ourselves with. Knowing the details of these processes makes it possible to prevent them.

The first is called “anodic current”, and results in “anodic corrosion”.

It is not necessary to have two different metals to create an electrical current; steel will spontaneously form anodic and cathodic regions only millimeters apart, and you will see tiny pits forming alongside undamaged areas of smooth steel if you look closely at a plate that’s spent a short time in the water.

Anodic corrosion can be stopped by using the correct “sacrificial anodes”.

The sacrificial anode is welded or bolted to the outside of the hull under water. This creates an electrochemical cell in which your hull is changed from the anode to the cathode. That's a good thing. the cathode remains intact.

The short story is;

In the Amsterdam inner canals, for really old boats, use a magnesium anode every 4 meters down the length of each side of the ship. They are a bit expensive, but much cheaper than the plate they save you. I get mine at Leegwater.

For boats after about 1910, or all boats in the Ij [harbor], use aluminum anodes instead.

You need new ones each time you go to the wharf, and although they normally have them in stock, it's a good idea to order them a week in advance. shipyard Van Laar in Ijmuiden always welds good anodes on for you.

The next time you pull your ship out of the water [after a few years], the anodes should be significantly depleted [worn down].

IF YOUR ADODES DO NOT CORRODE, THEY’RE NOT WORKING!!!

Here's why;

This is because the Ij is slightly salty [brackish]. Brackish water conducts electricity fairly well.

The water in the inner canals is quite fresh [believe it or not], and does not conduct well at all; more potential is required to induce the same voltage. Old steel was made using a different process, and has slightly higher potential voltage, that's why I use magnesium for my really old boat built in 1888.

You won’t find any books that recommend Magnesium anodes on steel boats. Several shipyards around the area now might do so, after my success with them.

The steel used on the old ships is different from the modern steel [it is NOT iron, despite what people think] it is a slight difference, but it can be measured; it’s about 0.2 volts.

This difference will cause any new steel you have welded under your ship to corrode [rust] at a higher rate, protecting the older steel. Unless you have anodes to corrode instead, protecting all the steel. This slightly higher voltage may also be why you need Magnesium for old boats in the inner canals.

The potential of the anodes is higher than the new or old steel, so they corrode first, the induced current flowing from them through the water to the steel through any pinholes or cracks in the paint or tar. This prevents it from rusting.

I'm not a scientist or an electrical engineer, so forgive me if my technical explanation isn't quite perfect; but I do have significant experience in this. I've been using this system for about 25 years on all my ships. It's working very well.

Paint;

Good bottom paint is also essential. The anodes can only protect small areas, the tiny breaks that are always in the paint. If there are large surfaces of metal exposed, the anodes will disappear in a few months.

Ask your shipyard which paint they use; ask if there are alternatives.

The shipyard business is very competitive, and they all try to have the lowest prices. That means they use the cheapest paint. The difference is as little as 300 Euros to use a better product; think about it, 300 Euros. How much is it costing you to go to the shipyard? I tell them to use the good stuff. If the yard doesn’t have it, they won’t mind if you bring your own. I sometimes buy at leegwater, at houthavens in Amsterdam.

STRAY CURRENT CORROSION;

This is the other source of corrosion on our boats. So far, I have not been able to pin down how much corrosion comes from this; but if you or any of your neighbors that use the same electric box on the street, have an electrical fault on board, there can be A LOT OF DAMAGE.

If any electricity gets to your hull, it then goes from the hull into the water; taking your metal with it.

If it’s more than 40 mA, it will shut off your electricity by tripping the ground fault interrupter [ardlek schakelar], [if it’s in working order] but 20mA for 3 years will do a lot of damage. 20 mA is a very small amount of electricity.

One solution often touted is isolating diodes in the safety earth line [often sold as a "Galvanic isolator"]. My opinion is that they are useless. You will be insulated for a volt or so of stray current through the safety earth line from shore, but it does nothing to protect you from stray currents originating in your ship, and higher voltage will just leak through.

There is one solution to stray current, and you can read it in any book on boat wiring.

The ISOLATION TRANSFORMER [scheiding transformator];

The idea is that the electricity from the land will flow only through the coils of the transformer, and then go back to the power company [they want it back anyway] without any of it getting free onboard, finding it's way to your hull, and doing damage.

New electricity is formed in the secondary coils of the transformer, and this is used on board your boat, and only on board your boat. There is no place for this new electricity to go, except back to the transformer where it came from; your boat is no longer connected to the shore power. This electricity will not go into the water because it can’t go home that way; home is back to your transformer.

For human safety, it is VERY important that there is an ardlek schakelar AFTER the transformer, and that the “Earth” wire of the onboard installation is connected to the center of your side of the transformer. This installation gives both your ship and people aboard [and swimmers] the best protection possible.

The “Earth” wire from the shore should NOT be connected to your onboard power network. It doesn’t need to be connected at all. This is important!

If you don't connect the safety earth line to the transformer, your central heating boiler won't work.

These transformers are expensive [about E1,000 for a 25A unit for your whole power supply], and they make an annoying humming sound. Mine is in a ventilated steel box with sound absorbing foam inside.

But; you only need to buy it only once.

You should not connect your power to any other boat once you’ve installed the transformer. When you do that, your transformer is no longer protecting you.

It is possible to supply power to another boat without compromising your electrical isolation; you have to connect the other vessel to the shore power line, and not to the output of your transformer.

It’s a good idea to have an outlet or two with its own fuse connected to the shore power line if you have another boat that needs to be pumped out or whatever.

Now I know that most people will find all this very complicated, and I suppose it is. If you show this to an electrician, he/she will understand what I’ve written; it’s all fairly obvious to an engineer.

One last thing; if you are isolating your power supply, you will need an isolation coupling in your gas line [if you have a city gas connection]. I checked several houseboat gas hoses, and all of them were conducting. They have wire inside. However some [not all] gas meter boxes I checked in Amsterdam have an isolation coupling between your connection ant the city's gas network. The pipe size is one inch, and it doesn’t matter whether you put it on the ship or on the pipe from the wall.

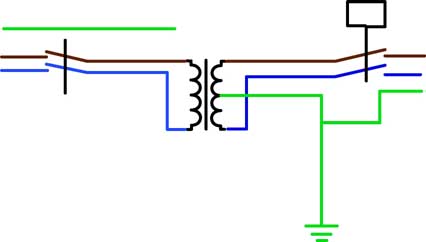

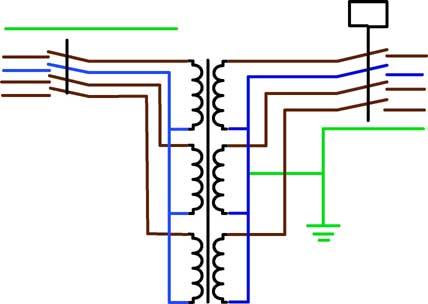

Isolation transformer wiring for a boat [color codes for Europe only];

Brown; phase, Blue; Neutral, Green; Safety earth

Single phase

mains switch GFI [aardlekschakelaar]

shore supply ship

Three phase isolation transformer wiring

Mains switch GFI, Ardlekshaakalar

Shore Ship

I hope this all helps someone out there. You can write to me if you have any questions;

Please feel free to link to this page

If this page does not display properly in your browser, please let me know!

Home | Contact | Terms | Realengrachtt | Vrije Muselaer | Watergruwel| FAQ |

| Amsterdam Links | houseboat tips | voltage regulator for dc alternators Pressurized Kerosene kiln burner India motorhome